What is Retreading?

Retreading is the process where selected and inspected worn tires called “casings” receive a new tread.

Types of Retreading

Pre-Q

Precure retreading uses tread rubber that has already been vulcanized with the new tread design. Pre-Q offers a wide variety of precured tread designs and sizes to meet your needs.

Pre-Q Retread Products

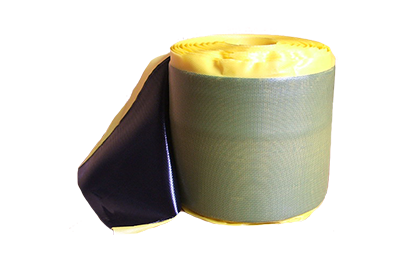

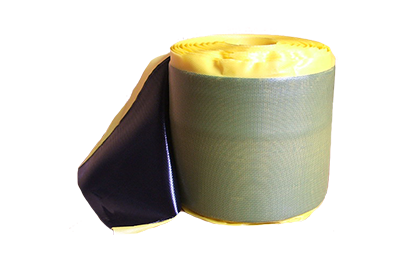

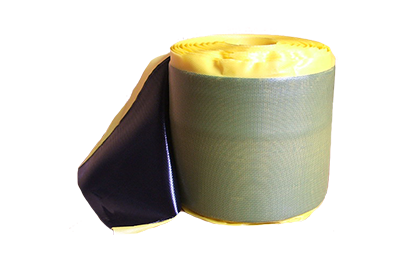

Cushion Gum

Premium rubber material that is used to adhere the tread to the casing through the vulcanization process. It is available in low 99ºC (212ºF) and high temperature 150ºC (300ºF) versions.

Extruded Cushion Gum (Az)

Preformed premium rubber material in the form of strips for AZ extrusion and can also be used for mold cure as well.

Strip for Extrusion.

Continuous strips with standard dimensions of 3 1/2 x 3/8, these measurements can be modified according to the client’s requirements. The product comes packed in cardboard boxes of 50 kg. (110.2 Lbs) or pallets of up to 900kg. (1984 Lbs).

Mini Extruder Rope Rubber

Premium rubber material is used in the retreading process to repair or fill damaged cavities before the vulcanization process.

Sidewall Cushion Gum

1 or 2-inch wide premium cushion rubber strips to improve the adhesion of the tread in the shoulder area. It also helps cover scuff marks and improves the overall cosmetic appearance of the tire.

Mold Cure

Mold cure retreading uses non-vulcanized strip rubber that is applied directly to the top of the buffed tire and then it is placed into a mold, which contains the tread design. The mold is then heated, which causes the rubber within the mold to vulcanize and adhere to the tire.

Products for mold cure

Cold Die Size

Rolled material, has an integrated cushion protected with a plastic polyethylene film. Maximun dimensions 24″ (610 mm) wide an 48/32 (38 mm) thick. This product is vulcanized in mold.

Premium Die Size

Premium material for high mileage applications. It is cushioned and protected with a polyethylene plastic film. Maximum dimensions 24″ (610 mm) wide and 48/32 (38 mm) thick. This product is vulcanized in mold.

Mining Die Size

Roll material that has an integrated cushion and is protected with a polyethylene plastic film. Maximum dimensions 24″ (610 mm) wide and 48/32 (38 mm) thick. This product is vulcanized in the mold.

Cold Strip

The material is used during the Building process. It is packed in cardboard boxes and protected with a plastic polyethylene film. This product is un-vulcanized and is used with an extruder.

Premium Strip

Premium material to be extruded an vulcanized. It is packed in cardboard boxes and protected with polyethylene plastic film. This product is un-vulcanized and is used with an extruder.

Normal Cushion

Material used for repair and in the retreading process.

Wall Cushion

Rubber to protect the sidewalls of the tire and also for bead to bead retreading. It comes perforated and coated with an anti-stick agent.

Natural Wall Cushion

Thicker rubber used primarily to protect and restore the base of retreaded tires.

Plant Supplies & Accessories

We manufacture and distribute a wide variety of plant supplies and accessories for retreading.

Products

Universal type cement

Cement for the adhesion of the precure / rubber floor strips, preparation material and the renewal of tires through vulcanization, using a single type of cement for the precure systems (100 – 150 ° C) (212 ° F) and for mold 150 ° C (300 ° F).

Water based paint solution for tires

Water-based black paint to give retread tires a better look. It does not suffer from cracking, it does not attract dust, when washing the rim it does not fade and does not stain on contact with the skin. It can be used with a sprinkler or by brush.

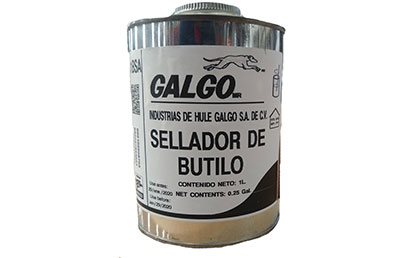

Butyl Sealant

Synthetic rubber product for use in tire repairs, restoring the tightness that the rim loses when it is repaired.

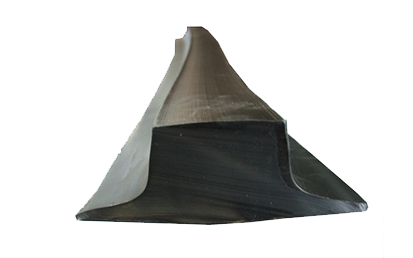

Rubber Wicking Pad

Improves sealing time of envelopes by vacuum. Made with rubber and resistant to high temperatures. Suitable for systems without rim with internal envelope and for system with rim trimming the ends.

Taco

Independent blocks for retreading OTR tires.

Retreading Process

1. Initial inspection

The casing is thoroughly inspected to determine if it can be retreaded.

2. Buffing & Skiving

The remaining old tread is removed from the tire.

3. Repair & Cementing

Patches are used to repair punctures.

An adhesive coat with cement is applied to the skived part of the tire.

4. Filling the injury & Preparing the tread

Injuries are filled with extruded rope rubber.

5. Building

The tread gets placed over the casing, using a high-tech building machine.

6. Tire Preparation

The tire is placed inside an envelope to prepare it for the vulcanization process.

7. Curing

Tires go through the vulcanization process in a chamber which securely adheres the tread to the casing.

8. Final Inspection

The tire gets examined to ensure that all repairs are properly done. Once the tires pass the final inspections, they move on to the final finishing stage.

Why Retread?

Environment

Retreading a tire uses less oil than producing a new one; this way, we save natural resources and decrease the number of tires in landfills.

Are retreads safe?

The real questions is, if retreads aren´t safe then why are they running on airplanes, school buses, ambulances, fire trucks, and many other critical applications?

Cost Savings.

Retreading a premium quality tire can result in a savings of 20% to 50% of the original cost of the tire.

Tread Catalog

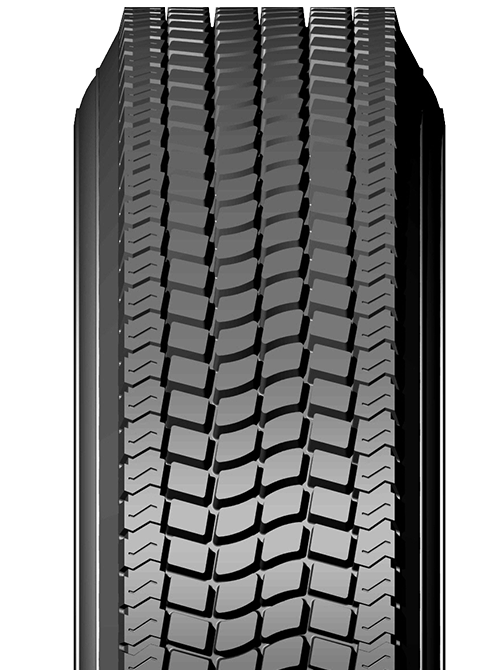

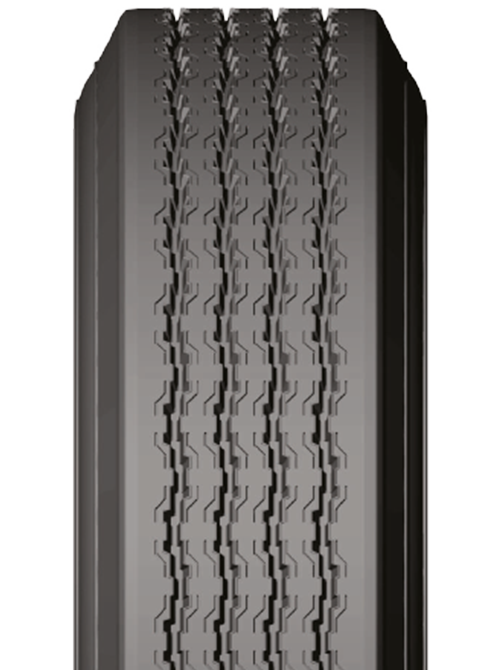

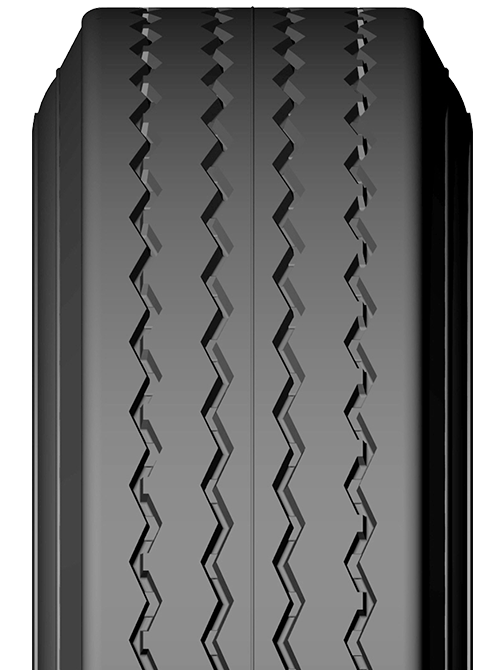

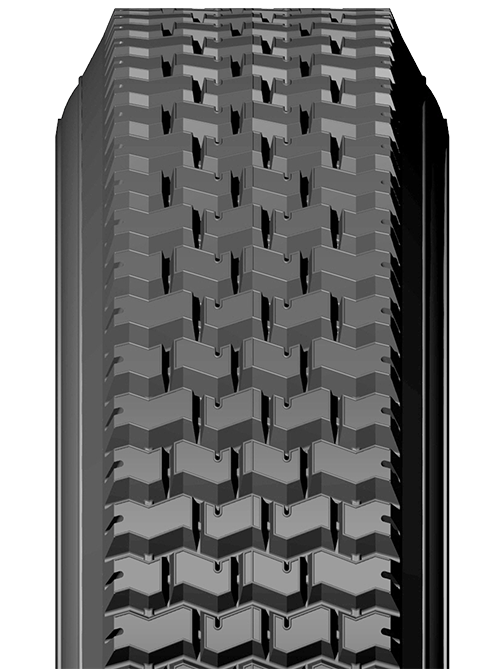

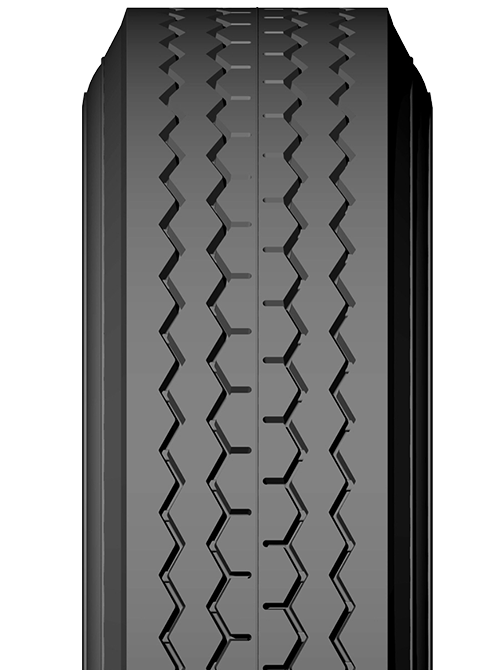

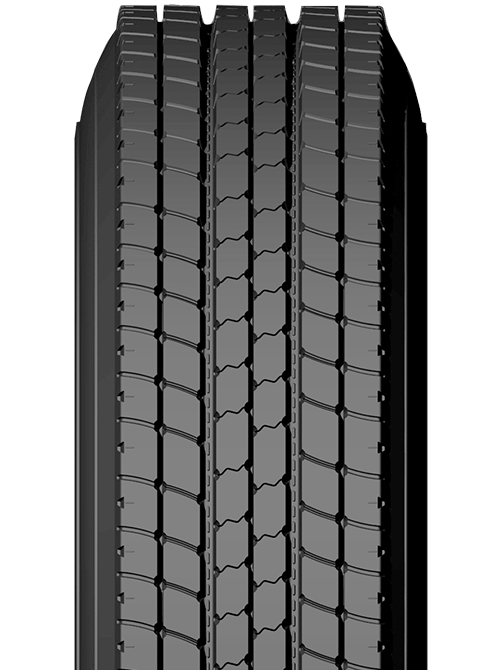

Application

- Road: For main roads of two or more lanes.

- Distance: travels over 310 miles.

- Speed: Steady and sustained speed and high-speed periods.

- Type of load: Heavy and medium.

- Vehicle type: Truck, bus and trailer.

- Features: Without stop & go.

Get to know our catalog

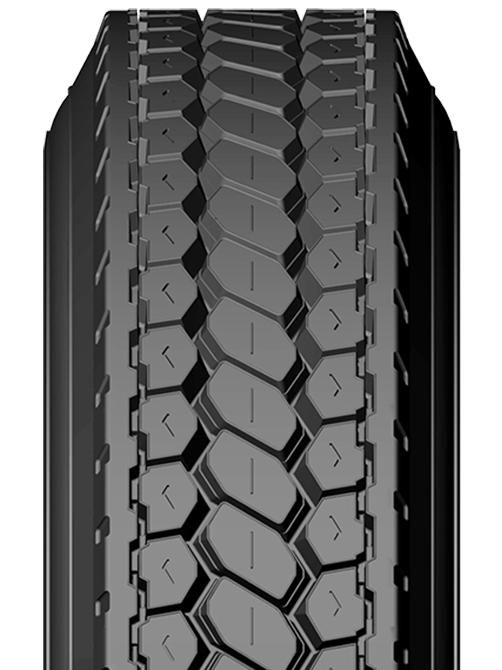

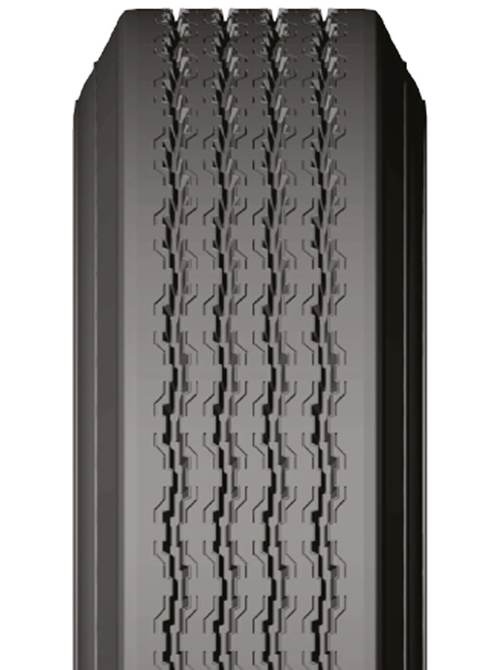

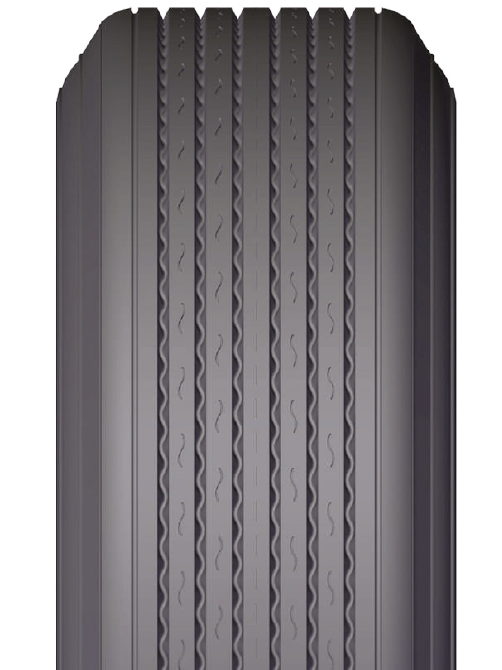

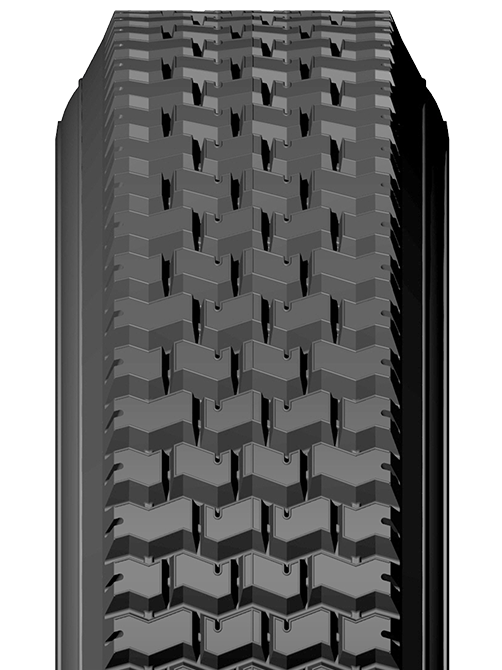

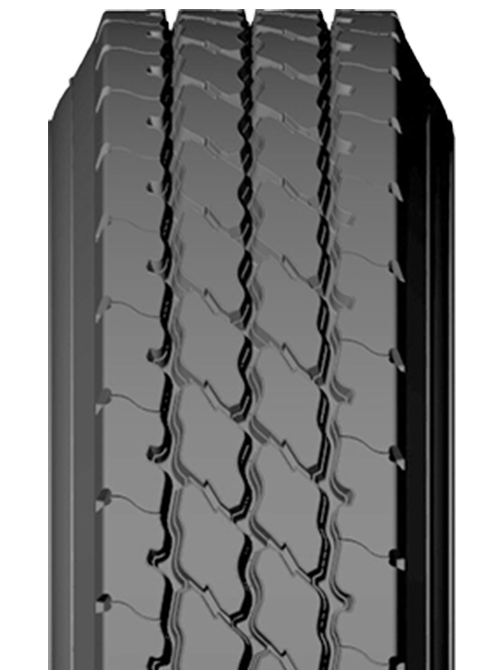

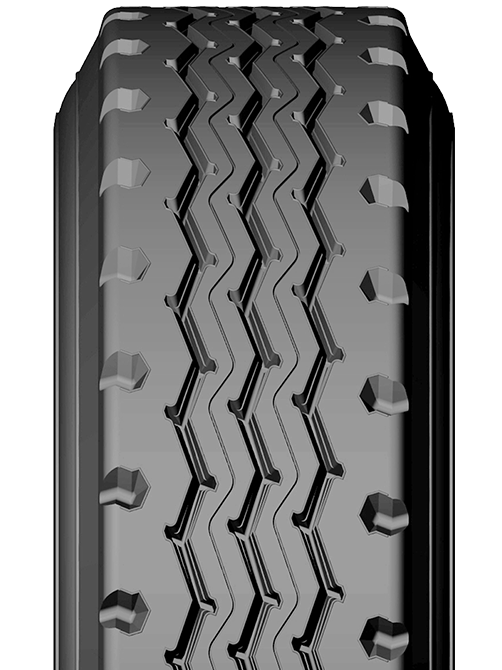

Position

- Road: Regional roads with two way lanes with curves & slopes.

- Distance: Less than 300 miles.

- Speed: Moderate speeds up to 55 mph.

- Type of load: Heavy & medium.

- Vehicletype: trucks, bus & trailer.

- Features: Hight stop and go.

Get to know our catalog

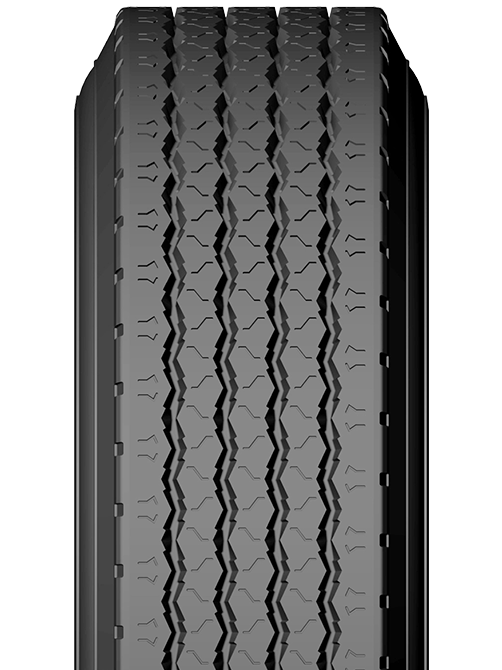

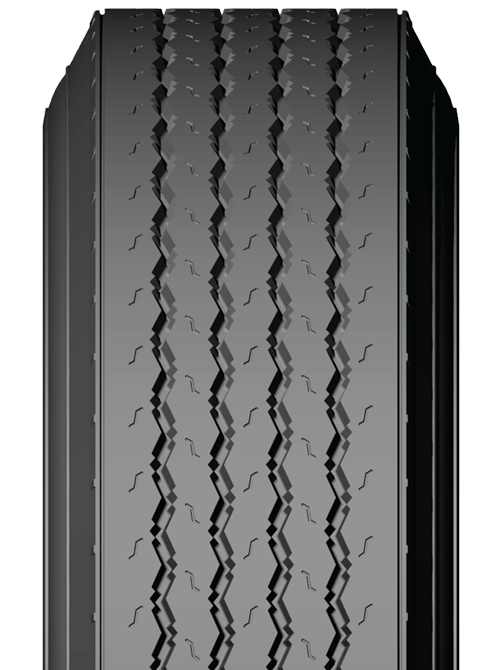

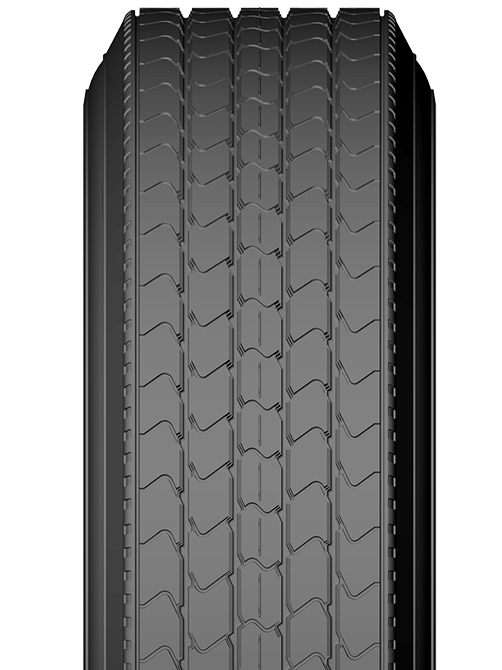

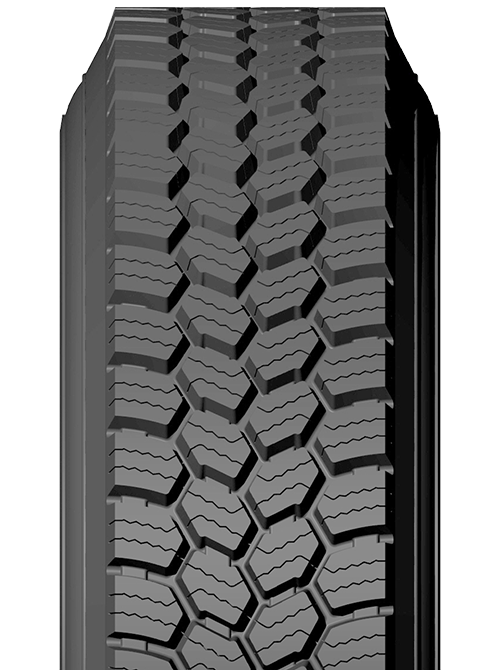

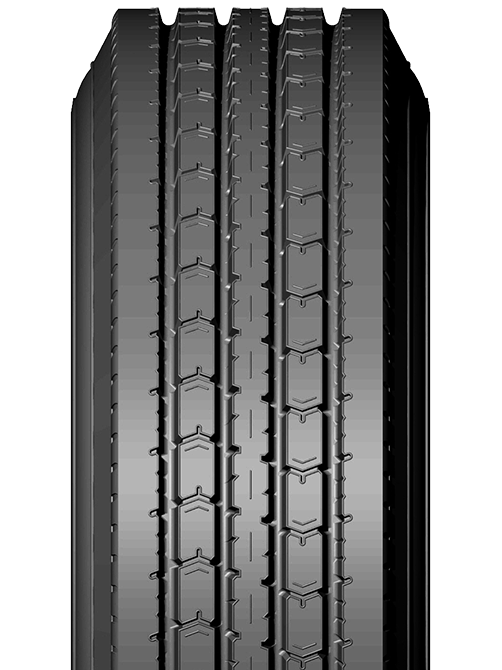

Position

- Road: Roads inside the city, cofined lane & outside city loops.

- Distance: Less than 125 miles.

- Speed: 50mph.

- Type of load: Medium & light.

- Vehicle type: Bus, pickup & delivery (commercial light truck).

- Features: High stop and go.

Get to know our catalog

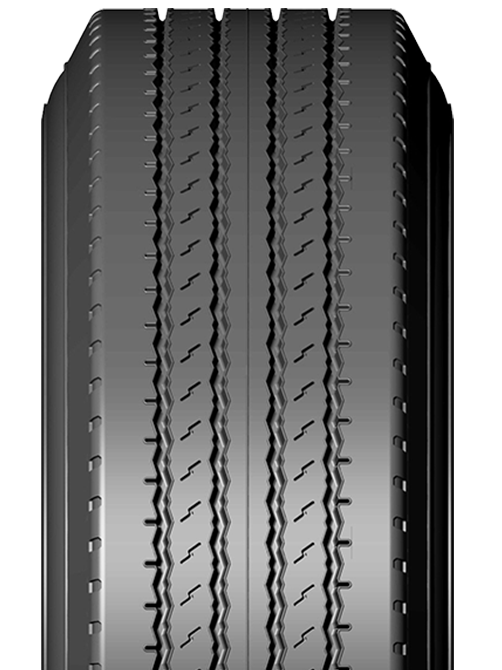

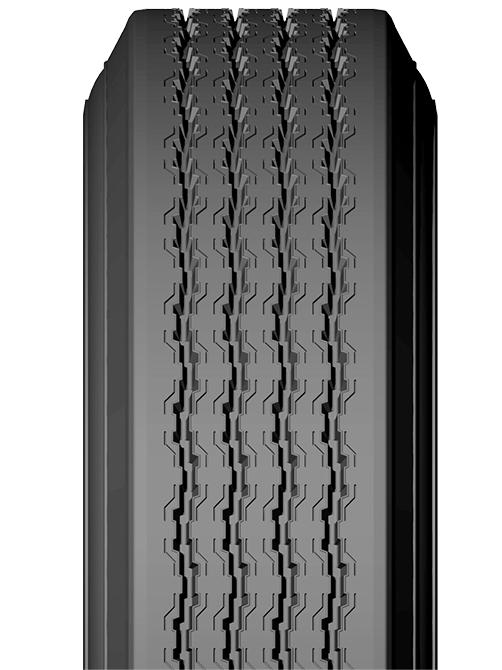

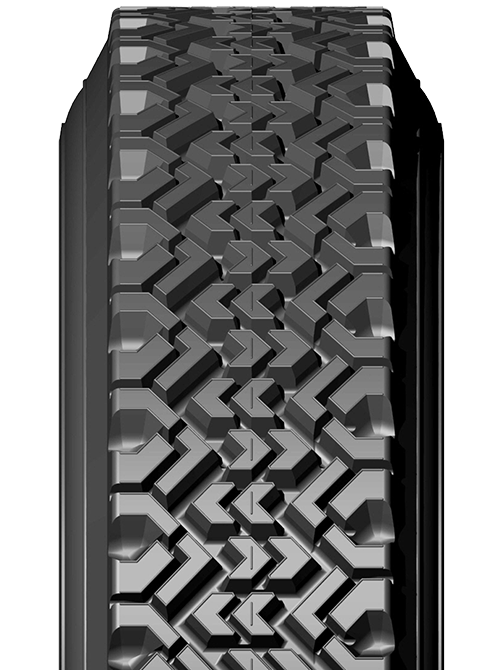

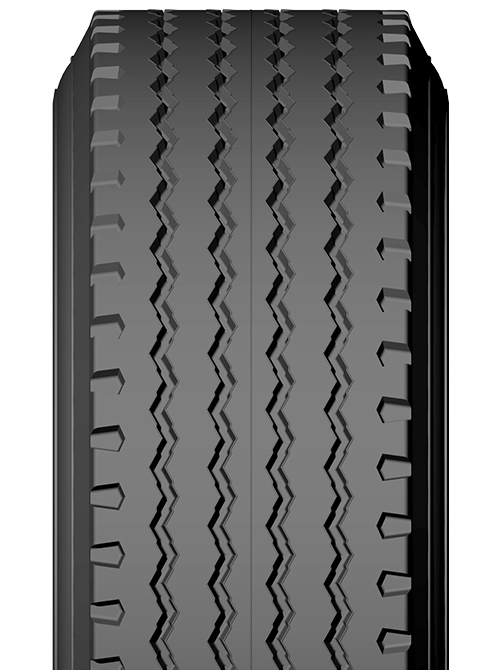

Position

- Road: Secundary roads & aggressive surface.

- Distance: Less than 95 miles.

- Speed: Less than 45 mph.

- Type of load: Specialized cargo, construction, agriculture & live stock

- Vehicle Type: Truck, torton & trailer.

- Features: 70% On 30% off.

Get to know our catalog

Position

- Road: Extremely adverse, mine sharpstone road.

- Distance: Less than 50 miles.

- Speed: Less than 30mph.

- Type of Load: Heavy, specialized, construction & forestal loads.

- Vehicletype: Truck, torton & trailer.

- Features: 30% on &70% off.

Get to know our catalog

Position

- Road: Extremely adverse, unpaved roads, mine, stone sharpstone road & mining blasting.

- Distance: 30 miles.

- Speed: Less than 25mph.

- Type of Load: Heavy, specialized, construction & mine.

- Vehicletype: Ford single and double axle vehicles, trucks &specialized vehicules.

- Features: 100% off

Get to know our catalog

Mexico

Mexico Europe

Europe